DEG Reboiler (Diethylene glycol)

A DEG (diethylene glycol) reboiler is a type of reboiler used in the chemical and petrochemical industries to heat and vaporize a liquid stream. It is typically used in the process of distillation and is designed to help separate and purify different components of a liquid mixture. DEG reboilers are typically used in the production of chemicals such as ethylene glycol and diethylene glycol.

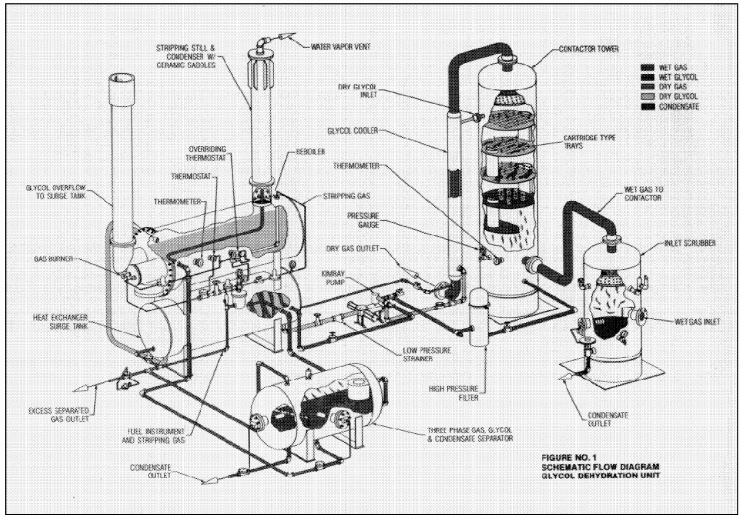

The typical DEG reboiler has several key components, including: • The reboiler vessel: The reboiler vessel is the main component of the reboiler and is typically made of steel or other durable materials. It is designed to hold the liquid stream that is to be heated and vaporized. • The heat exchanger: The heat exchanger is the component of the reboiler that is used to transfer heat to the liquid stream. It is typically made of steel or other durable materials and is designed to be efficient and reliable. • The heat source: The heat source is the component of the reboiler that is used to provide the heat that is needed to heat and vaporize the liquid stream. It can be a steam, hot oil, or electricity as a heat source. • The condenser: The condenser is the component of the reboiler that is used to condense the vaporized liquid back into a liquid form, typically it is a shell and tube type condenser, which is the most common design used.

The engineering specifications for DEG reboilers are: • Heat duty: typically from 10 to 100 million Btu/hr • Operating temperature: typically from 150 to 400 °F • Operating pressure: typically from 15 to 150 psig • Standard: API 660, ASME VIII Div.1

DEG reboilers are designed to be efficient and reliable in heating and vaporizing liquid streams. They are typically used in the process of distillation and are able to separate and purify different components of a liquid mixture. The heat exchanger provides efficient heat transfer to the liquid stream and the heat source provides the heat needed to heat and vaporize the liquid stream. The condenser provides the necessary condensation of the vaporized liquid. The use of standard materials and design make it easy to find a replacement or upgrade. The DEG reboiler is a key component in the chemical and petrochemical industries for its ability to heat and vaporize liquid streams efficiently and reliably.

You may also like

Image from https://naturalgasindustryhub.com/troubleshooting-a-glycol-dehydration-system/

Image from https://greasebook.com/blog/dehydrating-natural-gas-oil-gas-production/

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.